|

|

|

| Prototyp : Model : Jaguar XJR-10 / 11 |

|

Process, Part Six.

Introduction - 1 2 |

|

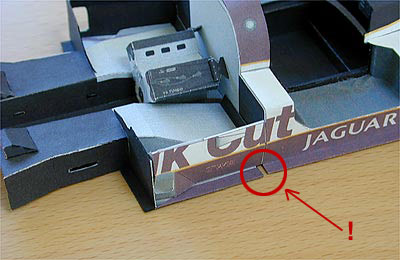

As the test build model progressed, some major issues were brought about by the undertray. While conceptually more "realistic", the undertray construction as separate component from the chassis floor created fitment and attachment issues. The tub and sidebox assembly difficulties noted in Process 5 still need to be addressed as well. Typical prototyp cars (the Sauber C9 and Eagle MkIII, for example) are designed with a central chassis monocoque and separate sideboxes all sitting on a separate floorpan and undertray assembly. The model assembly is to simply build up an entire undertray/floor/sidepods unit and drop in the monocoque. Tony Southgate's Jaguar designs (and his later Toyota TS010) use a full-width monocoque, incorporating the sideboxes and forward floor as integral stressed components. Replicating this in the model has proved to make it really difficult to build. The solution will be to combine the undertray and monocoque floor into a common part which the tub and sidebox assembly would attach to. This makes for a more kit-like construction, but perhaps will result in a better finished model |

|

|

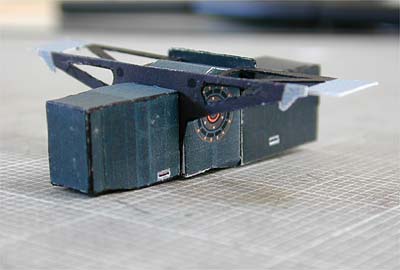

So while a long list of parts are rearranged and redesigned, the driveline's back-end is test-built. This assembly has to be fairly rigid as it will have all the rear suspension attached to it and will actually hold up the back of the car. Although much of this assembly is actually covered by the rear undertray, this first build version looks messy. The basic color of the unit will be changed to solid black so the paper edges will be easier to touch up and surface details will be made to contrast more. |

|

|

The complete basic driveline. Not done yet: the exhaust/turbo and induction systems should provide hours of challenging design work...

|

|

| The importance of details... > > |